This is a very simplified description of the process called “Lost Wax Casting”.

It is an ancient method and is still in use today.

A complete and detailed description can be read in the book “Anne Shingleton - TWENTYFOUR BRONZES” - See Publications

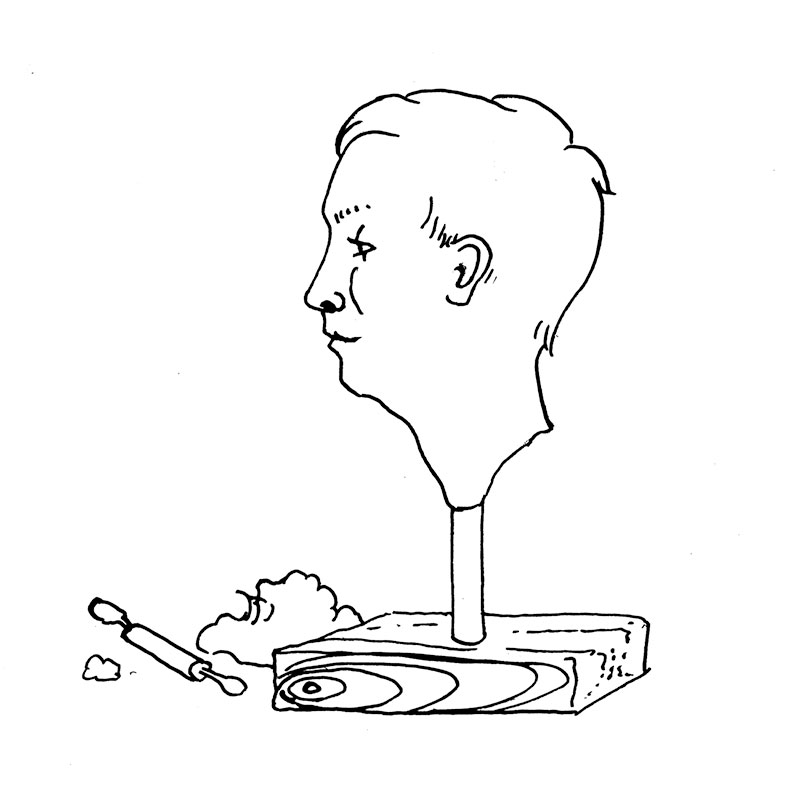

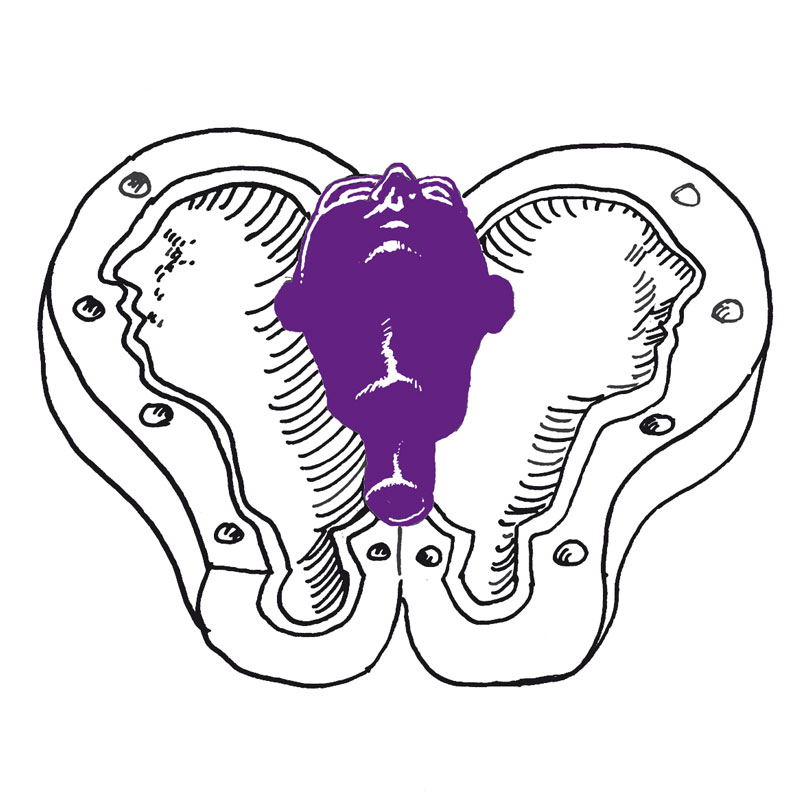

1

First, a model is made out of a material that can be sculpted; clay is most commonly used.

2

Then a mould is made by encasing the model in a rubbery layer of silicone and a second, reinforcing shell of plaster. When the two layers are set the mould is opened and the model is removed.

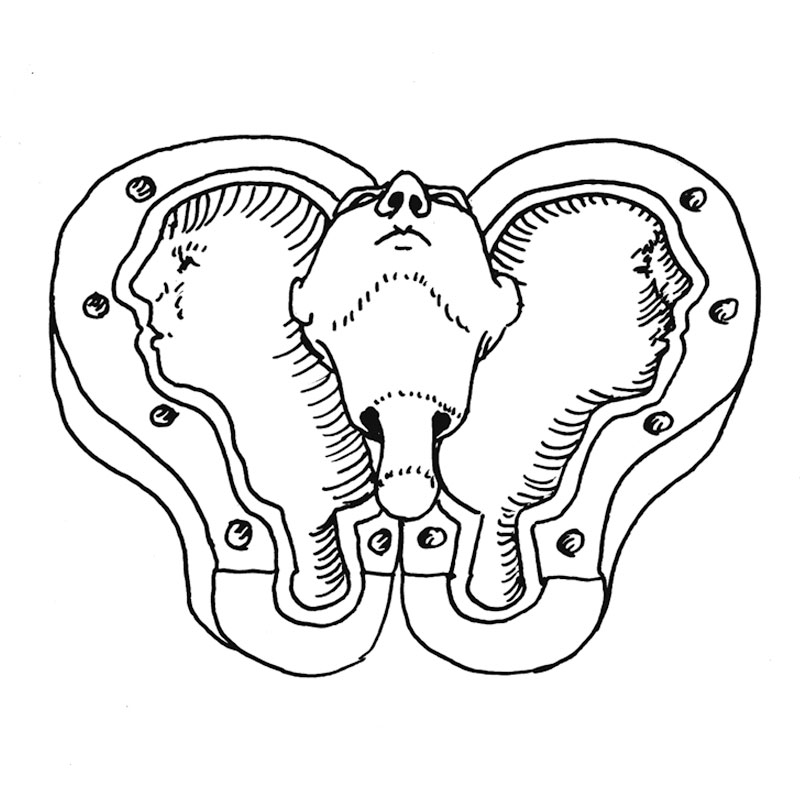

3

The empty mould is reassembled and hot, liquid wax is poured inside.

4

The excess wax is poured out when a layer of wax of about 0.5cm (1/6 in) thickness has solidified onto the inside of the mould.

5

When the wax inside is cool and has set hard, the mould can be opened and the hollow wax replica removed.

6

This wax replica is called the ”casting wax”, and at this point it is delicately worked over or “retouched” to correct any imperfections. This casting wax will be “lost” and replaced by bronze.

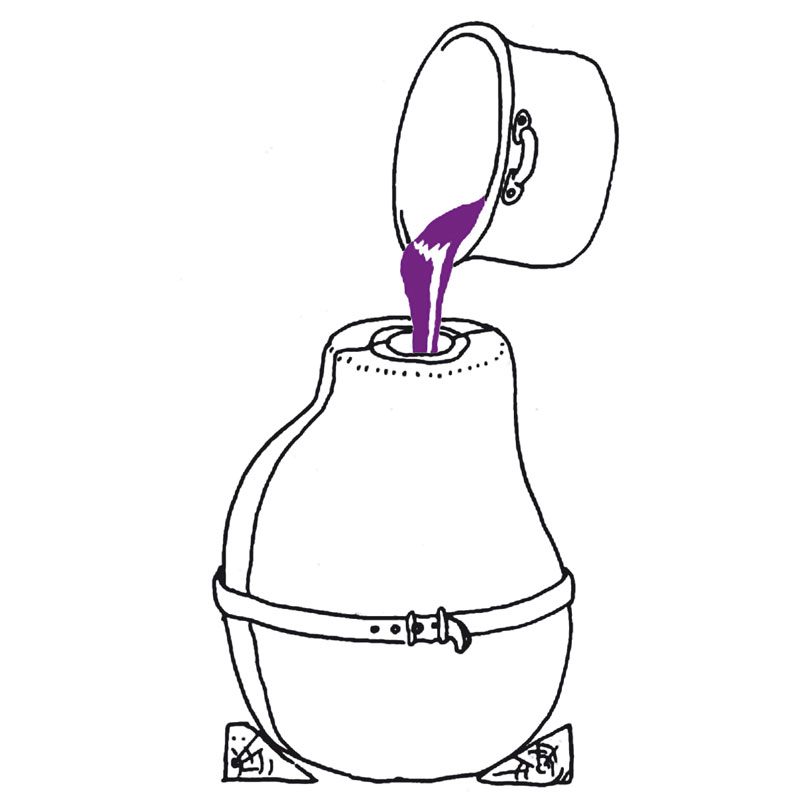

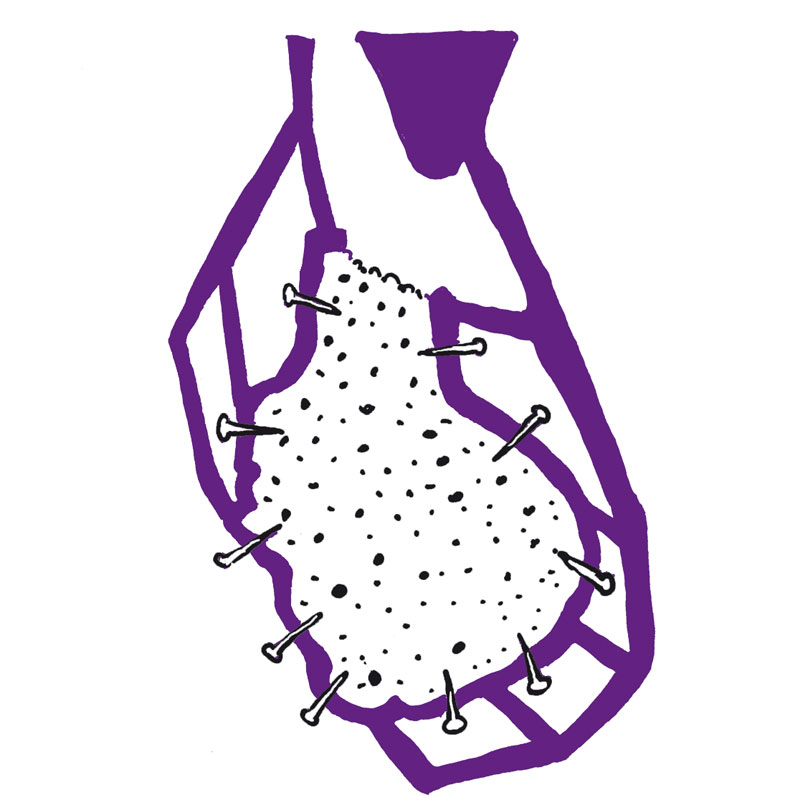

7

A heat-resistant material that becomes solid on firing is poured into the hollow centre. This is called the “core”.

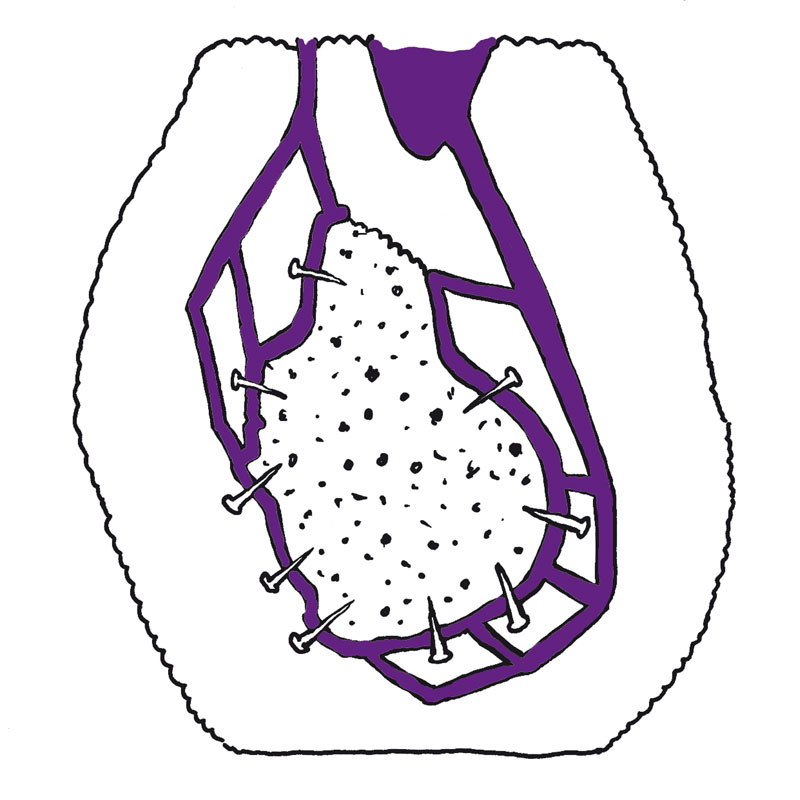

8

Next, bars of wax are attached to the outside. These are called “runners and risers” and will form pathways for the molten bronze to reach the sculpture from the funnel, and allow air to escape. Steel pins placed into the casting wax hold the core in place.

9

The whole construction is immersed in a fine refractory material, and forms a solid unit.

10

This unit is placed in a large kiln that heats to 700ºC so that the wax melts and flows out.

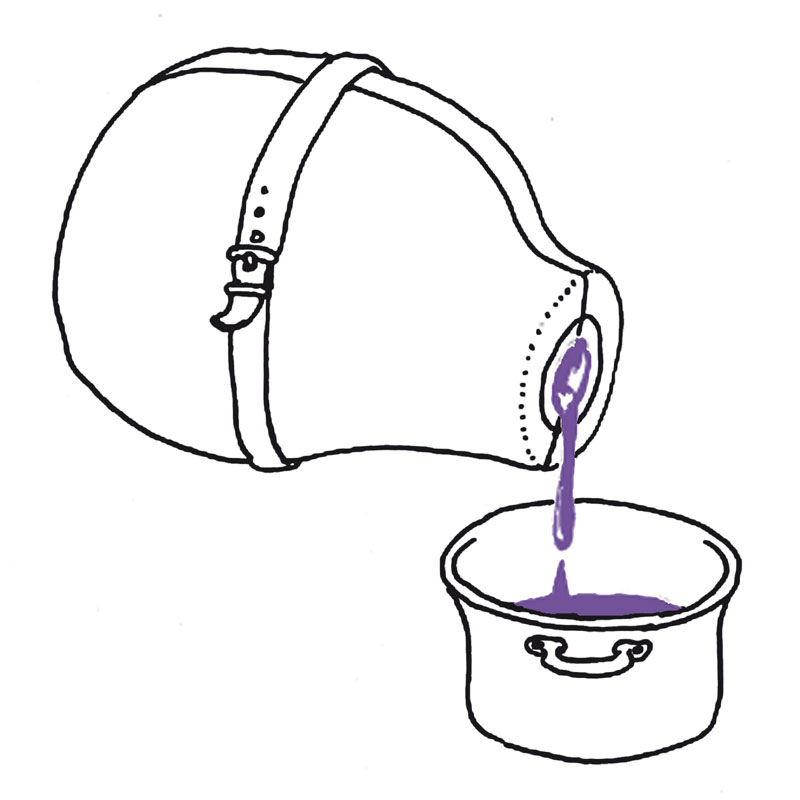

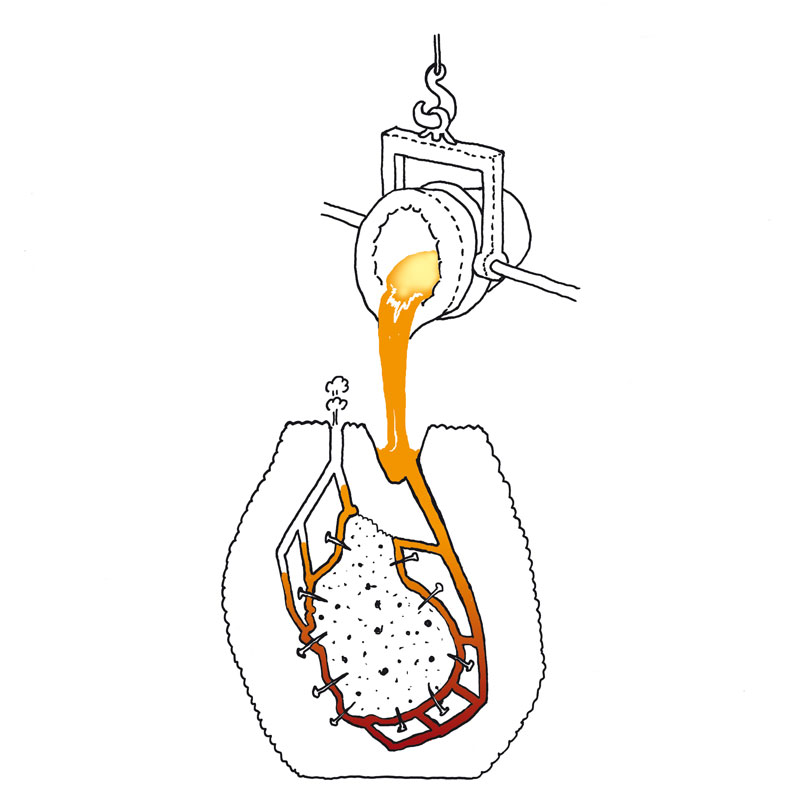

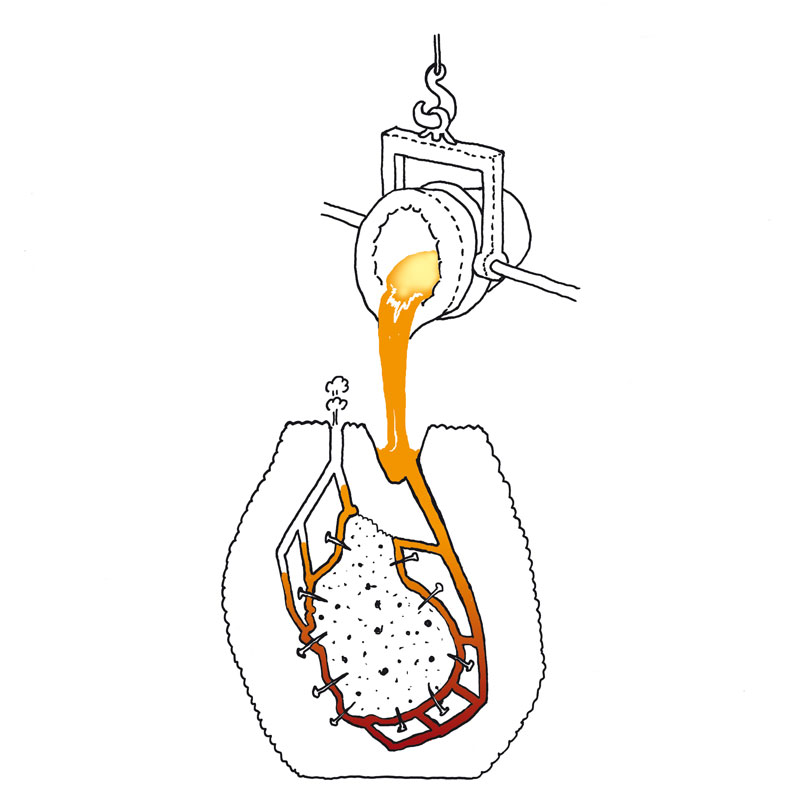

11a

The hot empty unit is taken out of the kiln and turned up the other way so that molten bronze can be poured into the funnel opening.

11b

Two men, wearing heat-protective clothing direct the pouring, with the assistance of special lifting gear to suspend the heavy crucible. The white-hot liquid bronze has a temperature of about 1200ºC – see the photograph at the head of this page.

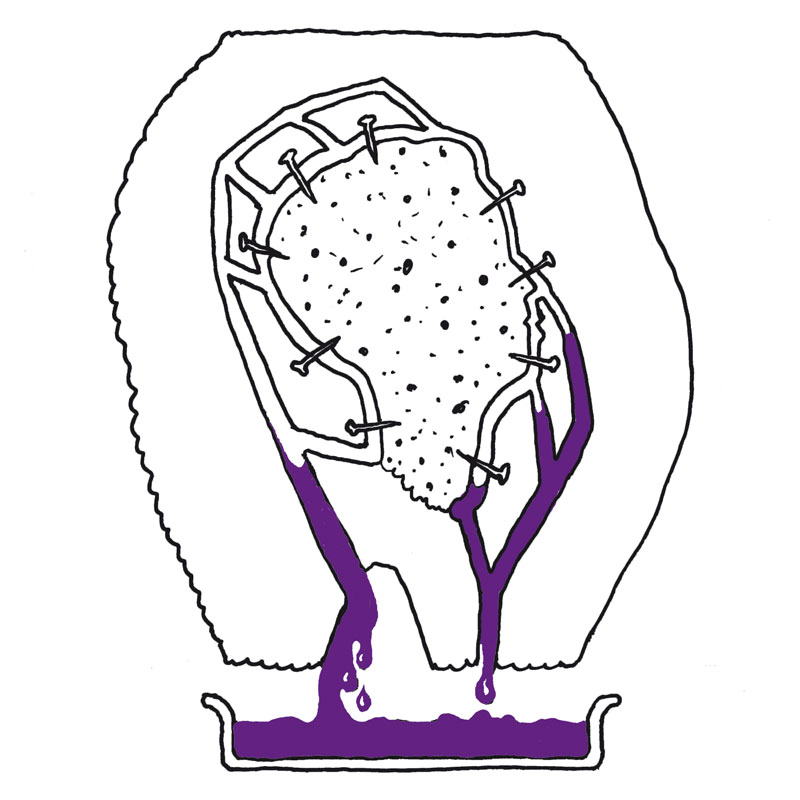

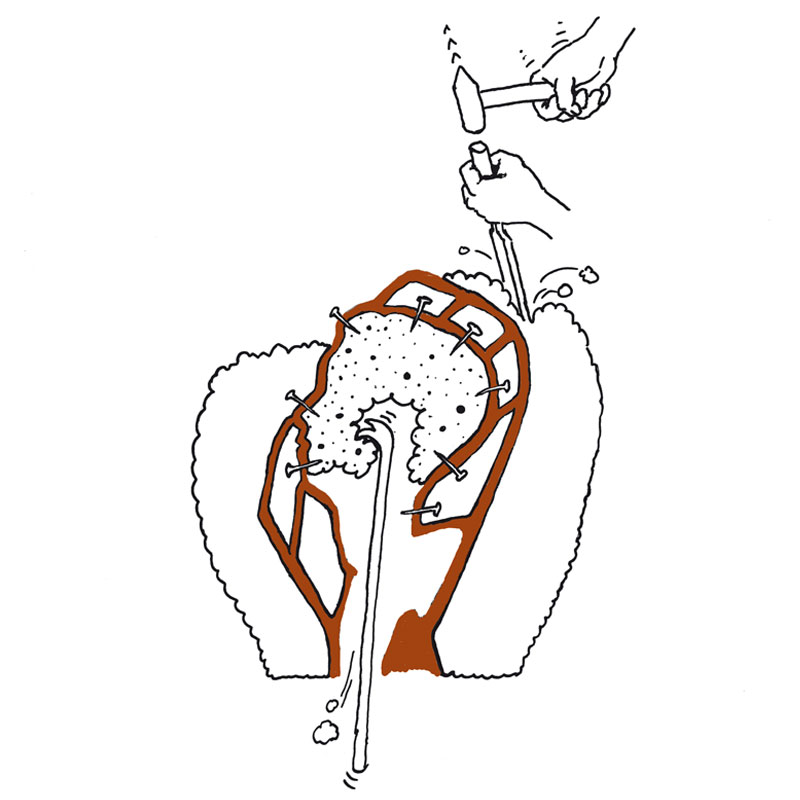

12

When the metal has hardened and cooled, the outside and inside material is removed.

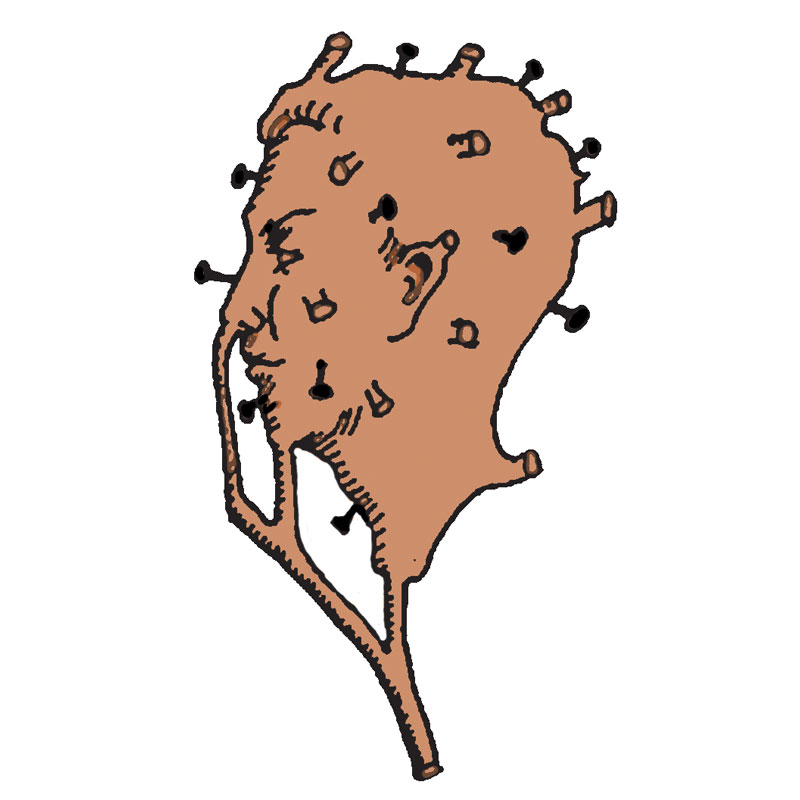

13

Then the runners and risers and retaining pins are cut off and their stumps filed down and integrated with the surrounding surface by filing and chiselling.

14

At this point there emerges a hollow bronze copy of the casting wax, which after polishing and “patination“ (treating the surface with acids and heat to produce the desired colour), results in the finished sculpture.